+61 3 62238677 | cbpi(at)wildisland.beer |

About Me

I’ve been interested in electronics and science all my life and have made a career of that in related industries.

I worked for Telecom Australia in radio and data/transmission from 1978 for 13 years covering almost every aspect of electronics design, construction, installation and maintenance. I worked on equipment using every frequency from DC to 40GHz and every power source from 2000Ah 2V batteries to 50kw television transmitters. I loved the challenges and learned a lifetime of skills

I left Telecom as a Senior Telecommunications Officer GR1. To progress in Telecom I would have to leave the technical field and become a Manager in some discipline I would not enjoy so I left and started a computer supply and services business in my Town, Roma in Western Queensland.

Eventually I moved to Tasmania, the island state, started a similar business here and am now semi-retired. I’ve renewed my interest in circuit design and fabrication over the past few years and saw the need for the CBPI project to have a better interface board. So, this is where we are now.

I wrote a full accounting package in the business language Clarion many moons ago, then integrated it with Reckon Accounting (was Quickbooks in Australia). Also a few Z80 (yes I’m that old) embedded controllers in the early 80’s, the old dots and tape and hand etched - give that at try doublesided!

I have no C or Python experience so I’m teaching myself that. Luckily I have a son who's a Doctor in that field to help me.

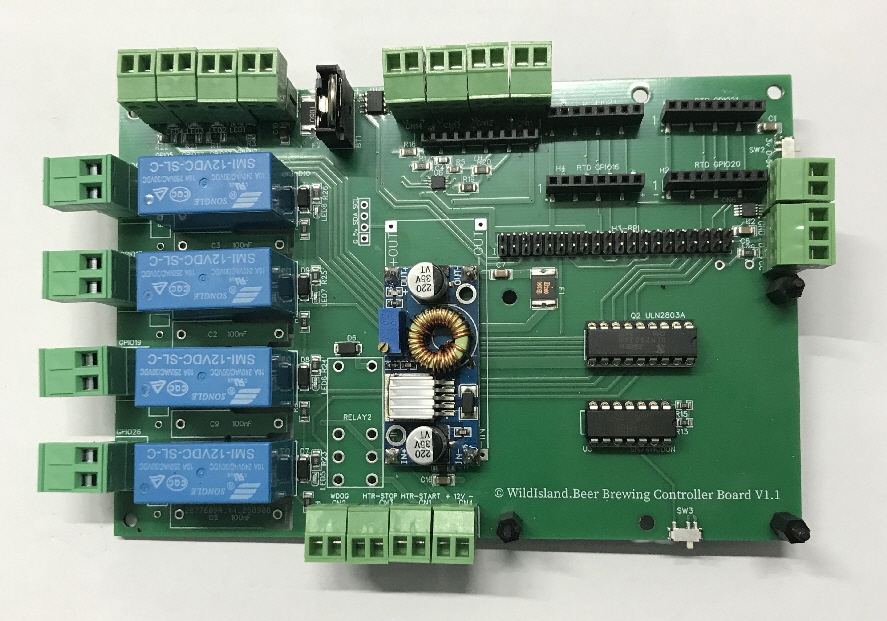

About the Board

I saw the need for this board as people were making ‘rat’s nest’ controllers out of various modules and sub-boards. This might work fine for testing and prototypes but it creates a dangerous device that can kill you and/or burn down your house. I saw the constant short supply of the CBPI hat in it’s various releases and so I decided to fix that.

The big problem was the ‘hat’ design of the official board. While convenient for mounting, it restricted what would fit in the space. So I turned that around and put the Pi on top of a standard 100mmx150mm board. This gave me plenty of room to add the things people were ‘bandaid-ing’ in their controllers. It also allowed me to design in safety features that protect against children, mains fail restarts and overheating kettles.

The board (V1.1) has these features:

100x150mm size, Pi mounts on top. 3D STL files on thingiverse for DIN rail mounts - 989474

4 relays with high current plugin connectors

4 RTD sockets - fits the MAX31865 board vertically with a rightangle pin connector.

4 SSR outputs with screw connector

Onboard DS3231 RTC - you'll need a CR1220 button cell

1-wire port and onboard ambient temp sensor DS18B20. Ability so increase the voltage and decrease the bus resistor.

4 port 0-5v ADC socket fits ADS1115 module vertically with a rightangle pin connector.

Onboard 12v buck to 5V 5A powers the Pi and the board.

Failsafe key-start prevents restart on powerfail return and has a fail loop where any break in the loop drops out the heaters.

Uses a Lucas keyswitch (think old Mini) to secure and start the system.

Hardware Kettle Priority that ensures you don’t overload your mains supply if you’re on standard 10/16A supply.

You can choose to bypass all the security if you want.